7 Warning Signs Your Generator Needs Maintenance

Generators play a crucial role in providing backup power during emergencies for businesses

and homes alike. However, neglecting generator maintenance can lead to failures at critical

moments.

Identifying early warning signs of malfunction can help you avoid costly repairs and ensure

your generator remains reliable. Here are seven signs your generator needs immediate

maintenance.

1. Difficulty in Starting

If your generator struggles to start or takes multiple attempts, there could be an issue with the battery, fuel system (pump, injector, filter), or spark plugs.

2. Unusual Noises or Vibrations

Strange noises like knocking, grinding, or excessive vibration indicate mechanical problems. These could be due to lose components, worn-out bearings, or issues within the engine. Immediate inspection can prevent further damage.

3. Excessive Smoke or Emissions

Diesel generators typically produce some exhaust, but excessive smoke-whether black, white, or blue-signals fuel, oil, or coolant issues. Diesel generator maintenance should include checking fuel injectors and air filters to prevent engine damage.

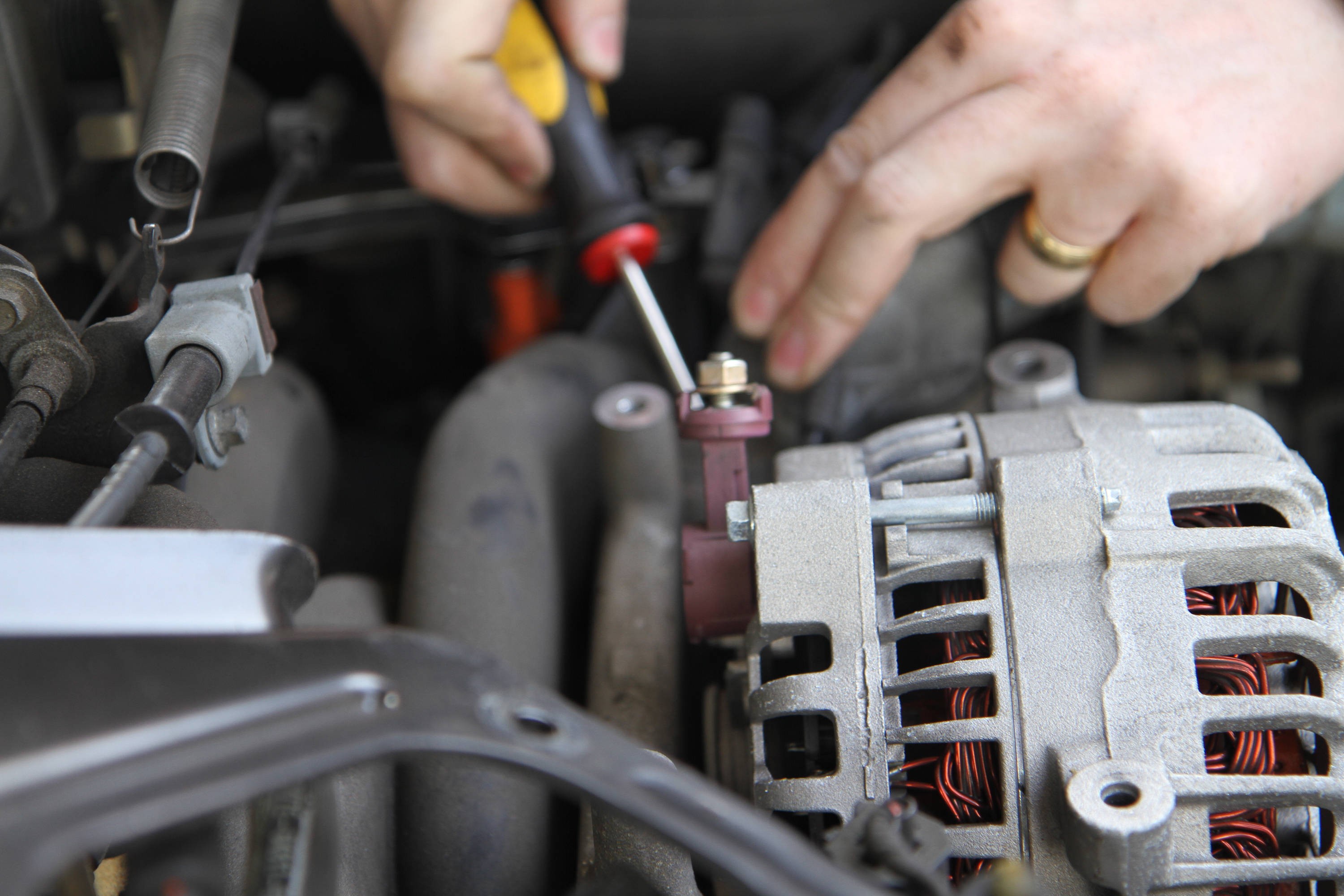

4. Low Power Output or Fluctuations

If your generator fails to provide consistent power or voltage fluctuations occur, it could be due to electrical faults, clogged fuel injectors, or worn-out alternators.

5. Fuel or Oil Leaks

Visible fuel or oil leaks around your generator are a clear red flag. Leaks not only waste fuel but also pose safety risks. Routine maintenance helps detect and fix leaks early to prevent fire hazards and efficiency losses.

6. Warning Lights or Error Codes

Modern generators have built-in diagnostic systems that display warning lights or error codes when something is wrong. Ignoring these signals can lead to major failures.

7. Battery or Electrical Issues

A weak or dead battery is a common cause of generator failure. Regularly inspecting battery terminals, charging levels, and electrical connections helps prevent startup failures and power interruptions.

Essential Generator Maintenance Checklist

To avoid unexpected breakdowns, follow this generator maintenance checklist:

- Inspect oil and coolant levels regularly.

- Test the battery and replace it when necessary.

- Check and clean fuel and air filters.

- Run periodic load tests to verify efficiency.

- Ensure exhaust and ventilation systems are clear.

Importance of Routine Diesel Generator Maintenance

Diesel generators require specific upkeep due to their fuel systems and engine design. Key diesel generator maintenance steps include:

- Draining water from fuel tanks to prevent contamination.

- Checking for soot buildup in the exhaust system.

- Inspecting belts, hoses, and connections for wear.

- Keeping the cooling system clean and free of debris.

Special Considerations for Gas Generators

Gas generators have unique maintenance needs, such as:

- Inspecting gas supply lines for leaks.

- Cleaning spark plugs regularly.

- Ensuring the cooling system prevents overheating.

Conclusion

Staying proactive with generator maintenance is crucial for uninterrupted power supply and long-term performance. Whether you own a diesel generator or a gas generator, keeping a close eye on these warning signs and following a structured generator maintenancechecklist will help you avoid costly repairs and unexpected failures.