MANUFACTURING PROCESS

At the heart of every Mahindra is technology that the customer can count on. Everything that goes into making of a Mahindra, whether it's the engine or the genset is world class. The entire process, from manufacturing facilities and technology to sales and services has received the highest rating for Total Quality Management and also won the Deming Prize- one of the most coveted awards in the world.

Mahindra Engines

One of the most important stages in the manufacture of a Mahindra engine is the J- bar assembly. This state-of-the-art process helps increase the speed of the assembly and at the same time allows Mahindra personnel to keep a tight check on component quality. The entire manufacturing process is guided by Poke Yoke concept; to achieve zero defects in the production line. This involves a robust design of the manufacturing systems and processes coupled with education and awareness about possible errors to achieve a high build standard in the engines. No wonder all Mahindra engines rate high on performance and dependability. Click here to view the J-bar Assembly

One of the most important stages in the manufacture of a Mahindra engine is the J- bar assembly. This state-of-the-art process helps increase the speed of the assembly and at the same time allows Mahindra personnel to keep a tight check on component quality. The entire manufacturing process is guided by Poke Yoke concept; to achieve zero defects in the production line. This involves a robust design of the manufacturing systems and processes coupled with education and awareness about possible errors to achieve a high build standard in the engines. No wonder all Mahindra engines rate high on performance and dependability.

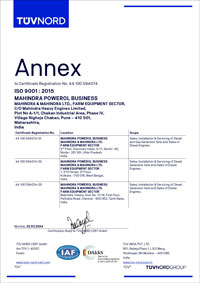

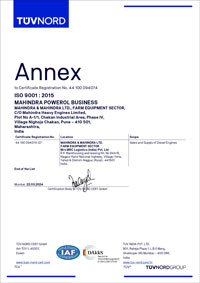

Diesel Gensets

Mahindra Powerol is today one of the largest manufacturers of Diesel Gensets in its range. These gensets are manufactured at two state-of-the-art factories located at Pune and Delhi, with a combined manufacturing capacity of over 30,000 sets per annum. Just like the engines, the most important process in manufacturing of gensets is the J-bar assembly. In addition to this, the entire manufacturing process of the gensets is also guided by the Poke Yoke concept; to achieve zero defects in the production line. A strong design of the Mahindra systems and processes coupled with education and awareness of possible errors helps Mahindra achieve a high build standard in its gensets. Component Machining - Because critical components are best made in-house Mahindra's has its very own facility for the machining of critical components. This helps Mahindra achieve and maintain very high standards in the fit and finish of all critical components. So the next time you buy a Mahindra engine or a Mahindra genset, you know you have a world class technology working for you.